time:2023-11-25 22:53:50Views:

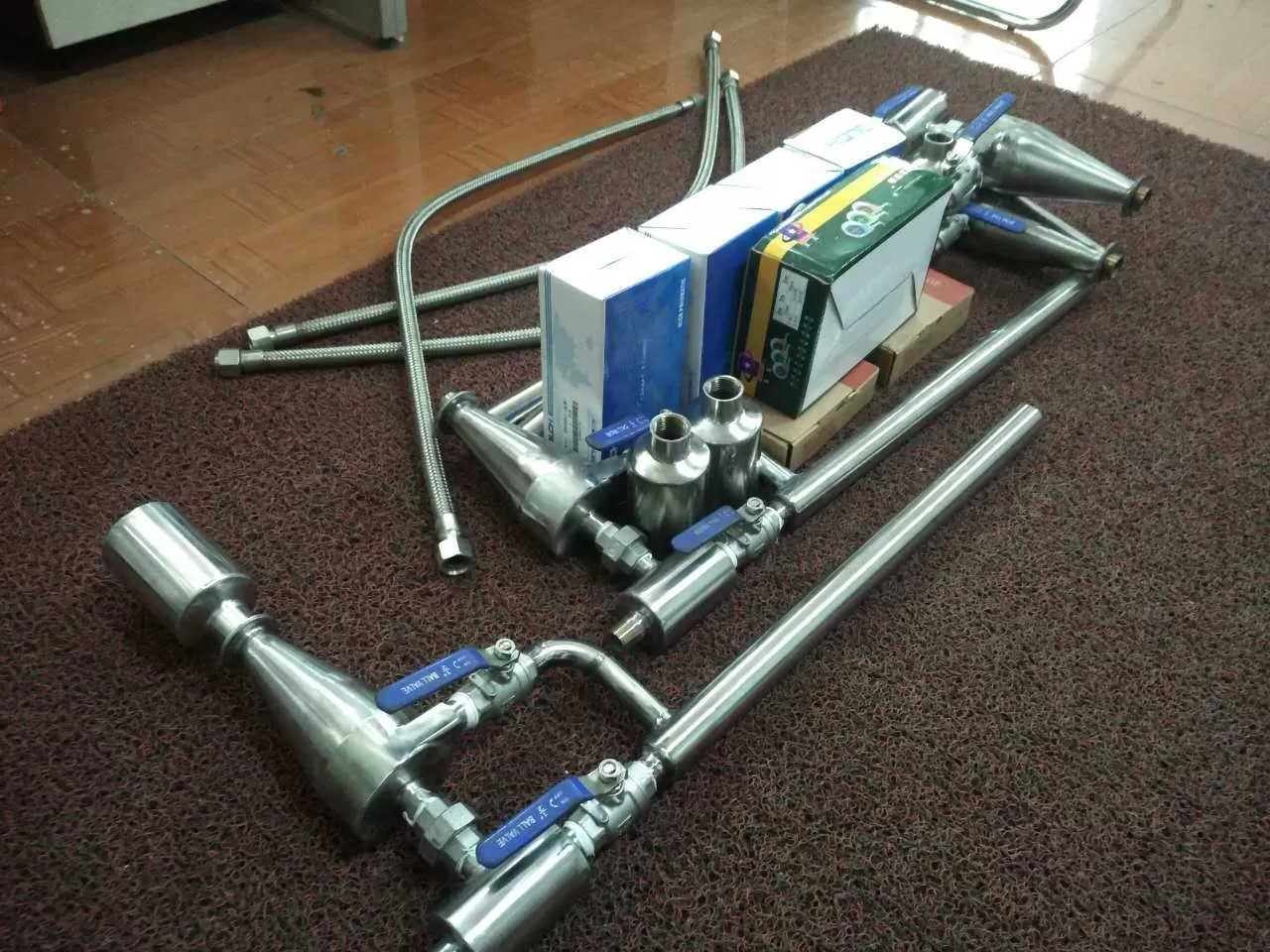

The oil injectors produced by Lianyungang Lingdong Electromechanical Equipment Co., Ltd. generally consist of nozzle filters, expansion pipes, inlet pipes, etc., and are installed on the main oil pump. When the pressure oil is sprayed out at high speed through the nozzle, a vacuum is formed at the nozzle. By utilizing the suction effect of the free jet, the oil in the tank is brought into the diffusion tube for deceleration and pressure increase, and then discharged at a certain pressure. Enable the main oil pump to have a certain pressure and improve the reliability of its operation.

The functions of lubrication oil tank injector 1 # and injector 2 # for steam turbines:

-The general unit is equipped with two oil injectors, which are divided into an oil injector and a second oil injector, also known as an oil injector. The second oil injector is installed below the liquid level in the lubricating oil tank, and when the unit is put into operation at or near the rated speed. The oil injector consists of a nozzle, a mixing chamber, a diffusion tube, etc. After the pressure oil from the main oil pump passes through the nozzle, the oil velocity increases and forms a low-pressure zone in the chamber. The oil in the tank is pumped into the injector chamber, and then it is carried by a high-speed oil belt into the diffuser throat. The velocity decreases in the diffuser and is converted into pressure energy. Then, through an oil cooler, it is sent through a pipe to the bearing manifold and the main oil pump suction port. Diffusion - equipped with a rocker check valve at the back to prevent oil from flowing back from the system. A check plate is installed on the surface of the oil tank in the chamber to prevent backflow into the oil tank during the operation of the bearing oil pump. To prevent foreign objects from entering the oil injector, a detachable perforated steel plate filter screen is installed on the oil suction side of the injector. The oil injector is one of the essential equipment in the lubricating oil system of the steam turbine generator set. In the lubricating oil system of the steam turbine generator set, the oil injector equipment can be divided into oil supply injectors and lubricating oil supply injectors according to its working purpose. Its working medium is L-TSA 32 turbine oil, with a working oil temperature of 45 ℃~65 ℃. When the unit reaches or approaches the rated speed, it is put into operation.

1. Fuel injector:

During normal operation of the unit, sufficient oil is provided to the main oil pump, with a portion of the pressure oil at the outlet of the main oil pump as its power oil.

2. Lubricating oil injector:

During the normal operation of the unit, lubricating oil is provided to the bearings of the steam turbine generator set, and its power oil is still part of the outlet of the main oil pump.

The installation of oil injectors requires attention to the following two aspects:

3. Assembly and installation:

The installation of the oil injector and its impact on energy are different. When installing the nozzle of the oil injector and lubricating oil injector, the nozzle bracket and inlet pipe flange must be tightened to ensure high-pressure oil leakage. The flatness and smoothness of all adhesive surfaces should be -.

4. Maintenance and upkeep:

When the oil injector is transported to the site after leaving the factory, if it is not immediately put into use, it needs to be repainted and sealed for protection. If it cannot be installed or filled with oil within two months of arriving at the site, it should be installed. The oil injector must be disassembled and inspected to remove rust and dirt. During the overhaul of the unit, the oil injector needs to be disassembled and inspected, and the nozzle should not be inspected. The surface roughness of the spray hole should reach the surface roughness (arithmetic mean of the contour deviation within the sampling length) R α The upper limit value is 3.2 microns. If there are any scratches or indentations, they need to be replaced.

The steam seal heater adopts a horizontal U-shaped surface heat exchan...

The steam seal cooler generally adopts a horizontal U-shaped surface h...

The air cooler adopts finned tube material, single metal finned tube a...

The waste heat recovery device, also known as the energy collector and...

The U-shaped tube is used as a cooling tube for heat exchange tubes, a...

Overview of condenser tube replacement and condenser stainless steel t...

Welded steel pipes (also known as slotted pipes and welded pipes) are ...

Welded steel pipes (also known as slotted pipes and welded pipes) are ...

Manufacturer of shaft seal heaters, also undertaking pipe replacement ...

Welded steel pipes (also known as slotted pipes and welded pipes) are ...

Steam turbine oil-water cooler pipe replacement, marine oil-water cool...

When purchasing a column type oil cooler for tube and core replacement...

The automatic steam liquid two-phase flow steam trap, also known as th...

The oil injectors produced by Lianyungang Lingdong Electromechanical E...

The oil injector is composed of a nozzle, a filter screen, an expansio...

A steam injector is a device that is powered by steam and is needed in...

Calculation of cooling area of sampling cooler 1: If the sample flow r...

The sampling of fly ash sampler is selected on the flue between the ou...

The use of carbon steel material in coal powder samplers has caused ma...

The working status of the oil injector and main oil pump, the analysis...

The oil supply and lubrication oil injectors are completely identical ...

The installation and operation of the coal powder sampler and mobile c...

The manual mobile coal powder sampler produced and manufactured by Lia...

The oil injector of Lianyungang Lingdong Electromechanical Equipment C...

The functions of lubrication oil tank injector 1 # and injector 2 # for steam turbines源頭廠家Copyright ? 2012-2023 Lianyungang Lingdong Electromechanical Equipment Co., Ltd all rights reserved